Concrete is one of the most fundamental building materials, found everywhere around us – from roads and bridges to buildings and airports. Yet, many of us are not even aware of its presence, despite concrete being one of the most widely used materials on Earth. The only resource more widely used than concrete is water. With population growth and urbanization trends, our need for concrete will be greater than ever. However, we face a significant challenge: cement production and its environmental impacts!

Environmental Issues of Traditional Cement

Cement is the binding agent that holds concrete elements together. The cement production process involves burning limestone and other materials at extremely high temperatures. This process produces a significant amount of carbon dioxide (CO2); for every ton of cement produced, almost one ton of CO2 is released into the atmosphere. This makes cement the second-largest source of greenhouse gas emissions, accounting for about 8% of global CO2 emissions.

In the era of global warming and climate change, this is a major concern. Innovation in cement production processes is essential to tackle this challenge. Without changes in this industry, controlling global warming is nearly impossible.

Carbon-Negative Concrete and Its Benefits

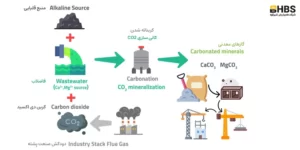

To address this issue, researchers are developing a new type of cement and concrete that can significantly reduce CO2 emissions. In the new method, the use of limestone in cement production is minimized, and the kiln temperature is lowered. This results in up to a 30% reduction in CO2 emissions in the cement production process. Additionally, instead of using water in the hardening process of concrete, CO2 is used, which is recycled from other industries and injected into the concrete.

As a result, the produced concrete not only significantly reduces CO2 emissions but also absorbs carbon dioxide, becoming carbon-negative concrete. This type of concrete can consume more CO2 than it releases during cement production. This change represents a substantial reduction in the carbon footprint of cement and has positive environmental impacts.

Using Recycled CO2 in Concrete Hardening Process

In this new technology, recycled CO2 from various factories and industries is used as a substitute for water in the concrete hardening process. This approach not only reduces CO2 emissions but also converts carbon gas into a useful material for concrete production.

Reducing Water Consumption in Concrete Production

Since this technology uses CO2 instead of water for concrete hardening, billions of liters of water are saved. This is particularly valuable in areas facing water scarcity.

Mechanical and Environmental Advantages of Carbon-Negative Concrete

This type of concrete not only effectively reduces greenhouse gas emissions but also surpasses traditional concrete in terms of strength and durability. Carbon-negative concrete is lighter, stronger, and more durable, and it can set in a shorter time, which increases productivity in construction projects.

Impact on Structures and Construction Projects

Carbon-negative concrete also offers additional benefits, impacting not only the environment but also the construction industry. Due to the new cement chemistry, this concrete is much stronger and more durable and can set in just 24 hours instead of 28 days. This significantly reduces project timelines and boosts productivity.

Another benefit of carbon-negative concrete is water conservation. Traditional concrete production requires a significant amount of water, which is a major challenge in water-scarce regions. By using CO2 instead of water, billions of liters of water are saved, reducing the strain on water resources.

For example, using carbon-negative concrete in construction projects can absorb as much CO2 as 100,000 trees do in one year. This type of concrete adds strength and durability to our structures, while simultaneously reducing environmental impacts and offering an innovative and sustainable solution for the future of the construction industry.

Conclusion

Innovation in cement production and the use of carbon-negative concrete demonstrate that traditional materials can be utilized in a more sustainable and eco-friendly way. By reducing greenhouse gas emissions and enhancing concrete performance, this new technology can revolutionize the construction industry and play a crucial role in combating climate change.