Concrete Canvas (Concrete Canvas) is one of the innovative technologies in the construction industry that has gained significant attention over the past two decades. Combining the flexibility of fabric with the strength of concrete, this material overcomes many limitations of traditional construction methods. Not only is Concrete Canvas considered a durable structural material, but it is also an environmentally friendly solution that can be implemented in challenging conditions, making it a groundbreaking advancement in construction projects.

What is Concrete Canvas?

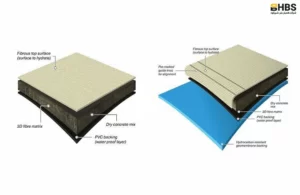

Concrete Canvas is a composite material with a layered structure comprising three main components:

- Base fabric layer: This flexible layer allows for application on uneven and irregular surfaces.

- Core dry concrete layer: A mix of cement and special chemical additives that activate upon hydration.

- Waterproof polymer layer: An external layer that prevents excess water and moisture, increasing the product’s durability.

How Concrete Canvas Works

The process of using Concrete Canvas is straightforward yet effective:

- Concrete Canvas is transported to the project site in the form of rolls.

- The rolls are unrolled and attached to the desired surface.

- Water is added (via spraying or immersion), initiating the cement hydration process.

- Within 12 to 24 hours, the material hardens into high-strength concrete.

Advantages of Concrete Canvas

Concrete Canvas offers several advantages over traditional concrete and other materials:

| Advantages | Description |

|---|---|

| Fast installation | Reduces installation time by up to 80% compared to traditional methods. |

| Easy transportation | Packaging in rolls simplifies transport. |

| Flexibility before hardening | Can be applied on asymmetric and uneven surfaces. |

| High durability | Resistant to erosion, UV rays, and chemical corrosion. |

| Environmentally friendly | Reduces energy and raw material consumption during production and installation. |

Applications of Concrete Canvas

Concrete Canvas is used in various projects, including:

1. Covering slopes and channel walls

Its resistance to erosion and ability to stabilize soil make it ideal for channel and slope coverings.

2. Building temporary and permanent shelters

In emergency and military projects, Concrete Canvas is used for shelters due to its quick installation and durability.

3. Repairing and strengthening industrial structures

For protecting pipes, tanks, and industrial structures against environmental damage.

4. Marine and port applications

Used in coastal stabilization, port wall coverings, and dock construction.

Limitations and Challenges

Despite its numerous advantages, Concrete Canvas has some limitations that should be considered in projects:

- High initial cost: Compared to traditional concrete, material and production costs are higher.

- Precision in hydration: Water quantity and hydration time must be carefully controlled.

- Limited roll dimensions: Rolls are produced in specific sizes, which may pose challenges for very large projects.

Improvements and Future Research

Numerous studies are underway to address limitations and enhance Concrete Canvas performance:

- Extending lifespan: Adding nanoparticles to increase durability.

- Reducing production costs: Optimizing production processes to lower the final price.

- Improving environmental compatibility: Using recycled materials in concrete composition.

Conclusion: The Future of Concrete Canvas

Concrete Canvas is considered a revolutionary technology in the construction industry due to its extensive advantages. With continuous development and further research, this material is expected to become one of the primary choices in modern construction projects.