Precast Concrete Wall

Given the advancements in the construction industry and mass production, the importance of increasing execution speed has become more significant, and the use of precast products has become more common. One of these products is the precast concrete wall, which is mainly used in the fencing of areas.

The water used in the concrete for precast concrete walls must be free of organic, acidic, and alkaline materials and should be clear and clean. Additionally, the use of standard A3 rebar with high tensile strength is more suitable for the construction of precast concrete walls or ready-made walls.

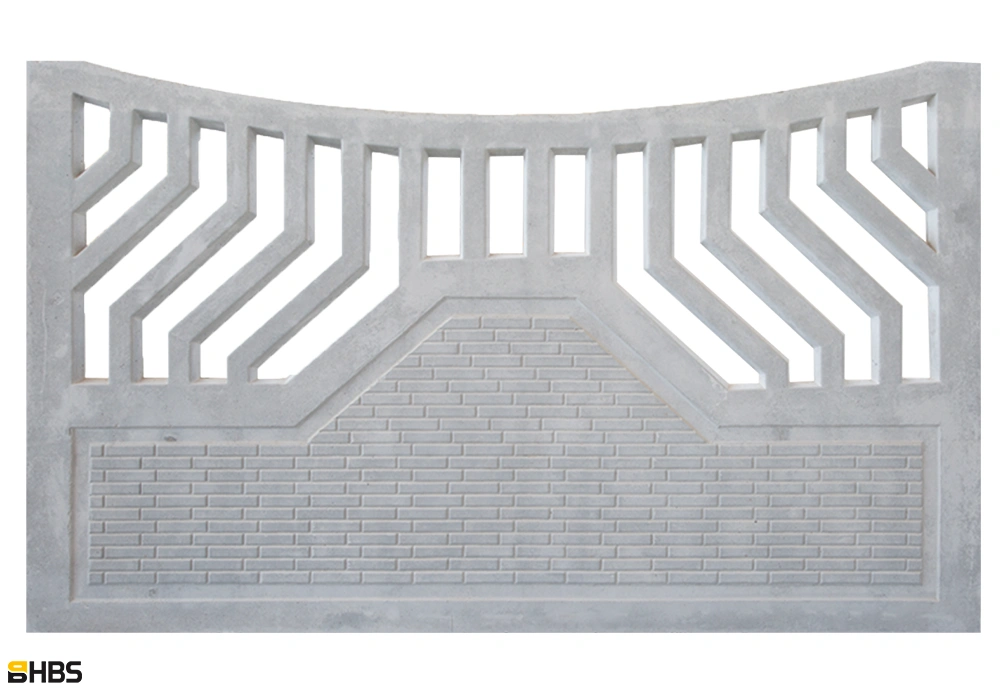

The image shown is from the Abu Zar Square concrete wall project in Yazd.

Types of Precast Concrete Walls

Precast concrete walls are constructed using concrete and rebar. There are three types of precast concrete walls:

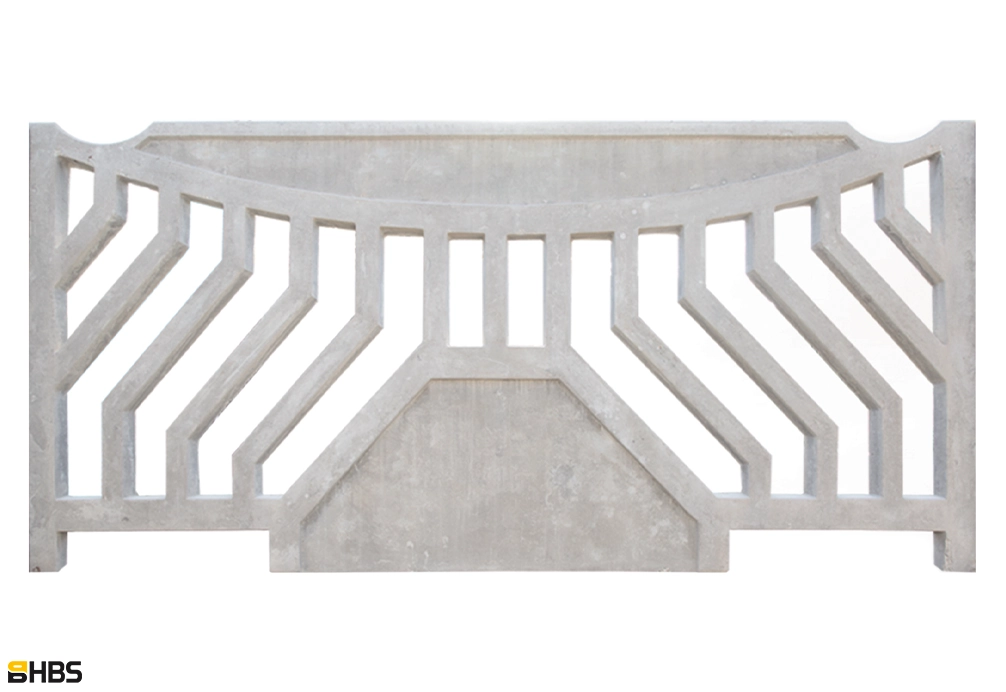

Single-Sided Decorative Wall (Simple and Railing Walls): This type of precast concrete wall is fully constructed in the factory and then transported to the building site. These walls are installed on one side of the building and are often visible from the side facing the street or a public area.

Double-Sided Decorative Wall: The double-sided decorative precast concrete wall is a type of precast concrete wall that is visible from both sides of the building. These walls are designed to be decorative and aesthetically pleasing. They are typically used in public spaces, parks, gardens, and even beaches to enhance the visual appeal of the area.

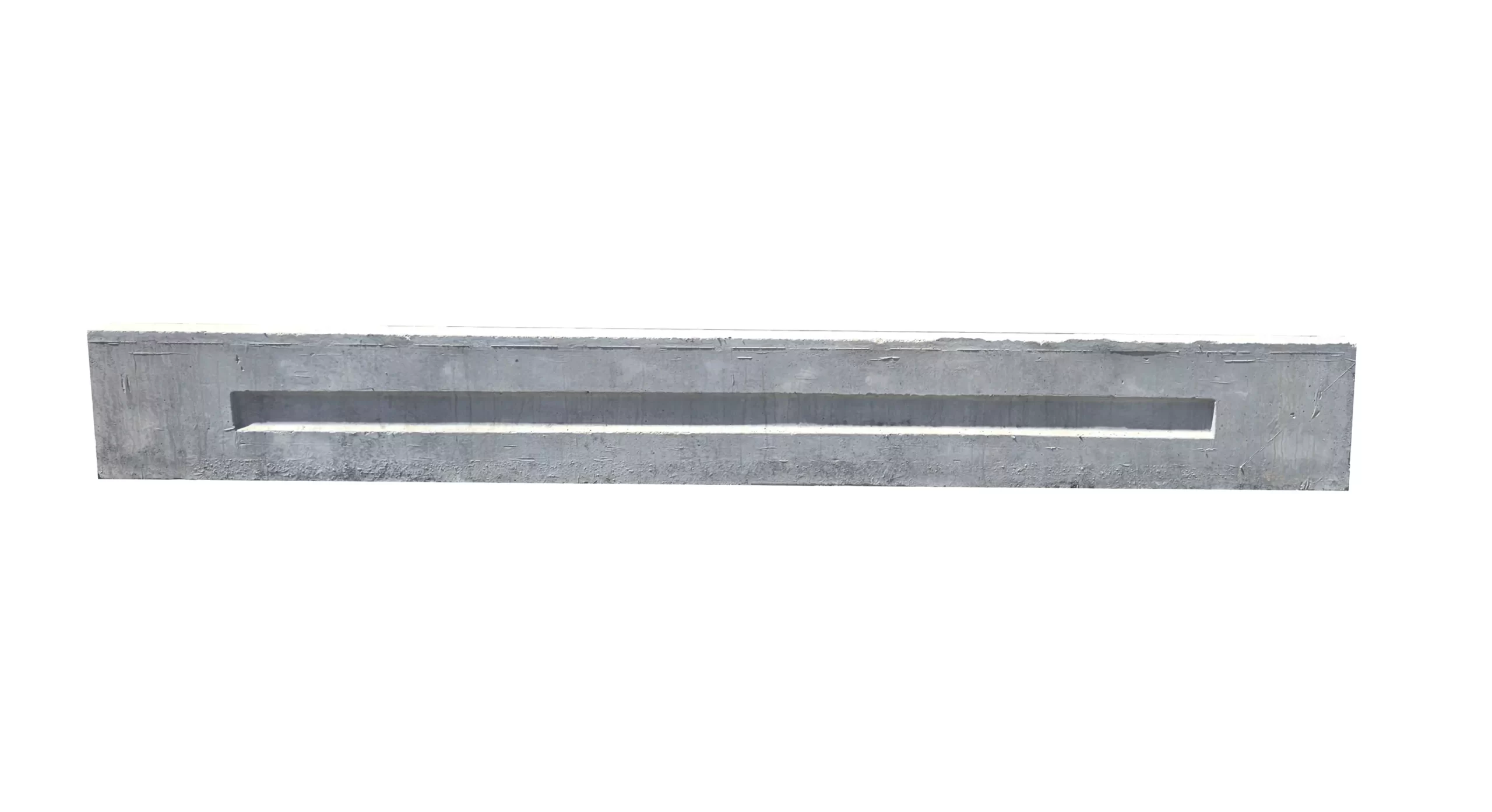

Self-Supporting Wall: The self-supporting precast concrete wall is a type of precast concrete wall that can be installed vertically at the desired location without the need for columns or other supportive structures. These walls are typically made of concrete and are capable of standing independently.

Price of Precast Concrete Walls

The price of precast concrete walls varies based on the thickness of the wall. As the thickness increases, the price of the precast concrete wall also increases. The type of wall, whether simple or decorative, significantly impacts the cost. Generally, single-sided decorative walls are cheaper, while double-sided decorative walls are more expensive per square meter compared to the other types.

Cheaper precast concrete walls include simple walls with minimal thickness, smaller rebar sizes, and lower-grade concrete. When purchasing a precast concrete wall, it’s crucial to ensure that the wall meets the necessary quality standards. Otherwise, buying a cheap wall may not be beneficial in the long run and could incur additional costs over time. In other words, the low price should not be the main criterion for selecting a precast concrete wall. It is essential to purchase from reliable sellers.

When buying a precast concrete wall, consider the area, desired wall height, and installation location. To determine the required area for purchasing a precast concrete wall, calculate the perimeter of the area. Precast walls are generally produced in heights and lengths ranging from 2 to 4 meters, chosen based on their intended use. Additionally, higher precast walls are typically manufactured in lengths of meters and should be considered when purchasing.

Affordable Precast Concrete Walls

Affordable precast concrete walls are an ideal solution for quick and cost-effective construction projects. These walls are manufactured using high-quality raw materials and advanced technologies to ensure they provide high quality and durability while also reducing costs.

HBS precast walls are cheaper than traditional walls due to the use of industrial production processes and advanced technologies. These walls are pre-manufactured in the factory and transported to the project site for installation, significantly reducing the time and costs associated with labor and raw materials. Additionally, HBS precast walls minimize the need for onsite formwork and construction operations, further reducing additional costs. Thus, using HBS precast walls not only saves costs but also improves the quality and speed of project execution.

If you have any questions or would like to request a quote, please contact Hamyar Beton Shirkooh Company.

To receive free consultation and price list, please fill out the form below.

To receive consultation and price lists for our products during office hours (8 AM to 2 PM), you can contact our specialists or submit a request for free consultation. We will follow up with you on the next business day.

Double-sided precast concrete wall

A double-sided decorative precast concrete wall is a type of wall manufactured from precast concrete with two visible sides. Using this type of precast concrete wall significantly increases construction speed and efficiency.

In addition to quick installation, these walls are portable and can be easily relocated to another location. Moreover, they offer high strength and durability, providing excellent resistance to various weather conditions. Various designs of these walls can be produced, and they can also feature engravings of logos or symbols of different organizations.

Installing precast concrete walls for fencing in harsh geographic and climatic conditions is feasible. Due to their construction method, these walls require less maintenance and repair compared to traditional walls. They can also be installed in various weather conditions, unlike traditional walls which face significant challenges in adverse climates. Another advantage of these concrete walls is their ability to be installed on steep surfaces. The video opposite showcases a precast concrete wall project located in Yazd city.

Installing precast concrete walls

Site Inspection: At this stage, the project site is inspected to ensure it’s ready for the installation of precast concrete structures. This includes assessing existing structures, preparing the surface, and reviewing necessary technical information.

Selection and Use of Suitable Crane: For handling heavy precast concrete structures, a suitable crane is chosen. At this stage, a crane with the appropriate capacity and power is selected to ensure proper lifting and installation of the structures.

Transportation of Structures to the Project Site: The precast concrete structures are transported to the project site using a crane or other transportation equipment. Safety and structural integrity are emphasized during this stage of transportation.

Leveling the Structure Surface: After unloading the structures at the site, the intended surface for installation must be leveled, ensuring it’s ready for installation.

Placement of Precast Foundations: Precast concrete foundations are positioned in predetermined locations. This involves determining the positions and dimensions of the foundations based on technical drawings and plans.

Pouring Lean Concrete and Watering the Foundations: Before placing the foundations, prepared lean concrete is poured and spread over the foundation. The concrete is thoroughly watered to cure properly.

Placement of Columns in Foundations: Columns are placed inside the foundations. At this stage, columns are positioned in specific locations within the foundations.

Installation of Roof Blocks: Precast concrete roof blocks are placed in their appropriate positions. These blocks are connected to each other using welding or locking systems to form the roof structure.

Installation of Precast Walls: Precast concrete walls are sequentially placed in their appropriate positions. This includes ensuring the walls are correctly positioned and securely connected to the columns.

Final Inspection and Testing: After installing all structures and equipment, final inspections and tests are conducted to ensure that the structures are properly installed and meet the required standards.

The use of precast concrete walls in large and complex construction projects

Increased use of precast concrete walls in large and complex construction projects can serve as an effective solution for improving performance, reducing costs, and accelerating project timelines in construction. Below is a more detailed explanation in this regard:

Increased Construction Speed: Time is crucial in large and complex projects. Using precast concrete walls as part of the building structure speeds up construction. These walls are manufactured off-site and transported to the installation site at the right time, significantly reducing construction and installation time.

Cost Reduction: Manufacturing and installing precast concrete walls typically reduce costs compared to traditional construction methods. This cost reduction is due to reduced labor time, optimal use of human resources, and efficient utilization of construction materials.

Enhanced Quality and Precision: Precast concrete walls, manufactured under controlled factory conditions, improve the quality and precision of structure execution. This translates to fewer structural errors and issues during the construction process.

Design and Implementation Flexibility: Precast concrete walls provide engineers and designers with greater flexibility in structure design and implementation. This flexibility is particularly effective in projects requiring diverse wall shapes and dimensions.

Given these advantages, the increased use of precast concrete walls in large and complex construction projects is recognized as a suitable and effective method for enhancing performance and efficiency in the construction industry.

The advantages of HBS precast concrete walls

One of our prominent advantages is the ability to install concrete components in locations with steep slopes, strong winds, and various temperature conditions. This unique feature allows us to perform flawlessly even in complex and challenging projects. Our products are designed to be adaptable to different conditions and are used in a variety of projects, including residential, commercial, and industrial buildings.

Closing Remarks

Prefabricated concrete walls, as a modern and effective method in the construction industry, come with their own advantages and specific challenges. Given the numerous potentials of these walls and the ongoing advancements in related technologies, a bright future can be expected for them. This future is likely to bring enhancements that ensure improved performance and efficiency of concrete structures. Therefore, these walls can serve as a sustainable and effective option in the design and implementation of construction projects.

The price of precast concrete products depends on many factors, including dimensions, type of materials and materials used in the part, size and shape, and its design. In addition to this, the cost of transportation, installation of the structure, and the hiring of contractors and professional workers are also added to the purchase price of precast components.

It is suggested that you contact us through the above communication methods for better information about the price of the factory door or the shipping costs

- Reducing construction and execution time

- High resistance and strength against weather conditions and natural disasters

- The possibility of construction in all weather conditions

- Reducing the cost of raw materials

- Reducing construction waste and reducing noise and dust

- The possibility of making and producing in different dimensions and sizes for special purposes

You can inquire about the price or purchase from the company in person or by phone

Yes, Sure

You will be surprised to see our quality and speed

If you want to visit the company, contact the collection management for coordination

Mr. Hakimian: (+98)9135508182

You can also contact us through other means of communication or social networks

HBS Precast Concrete Wall Reviews

4 reviews for Precast Concrete Wall

Ali –

I recently used a precast concrete wall for my garden project. The durability and ease of installation were exactly what I needed. Highly recommend Break Design precast concrete wall!

Manager –

Thank you for your feedback. We’re glad our precast concrete wall met your expectations. For consultation on concrete or additives, please contact us at: +989135508182.

J. Saman –

The precast concrete wall from HBS is of exceptional quality. It’s perfect for both residential and commercial applications. I was impressed with the seamless installation process and the robust finish.

Manager –

We appreciate your kind words. It’s wonderful to know our precast concrete wall provided the quality and ease of installation you sought. For consultation on concrete or additives, please contact us at: +989135508182.

Kaven Sean –

If you’re looking for a reliable and sturdy solution for your construction needs, the precast concrete wall is an excellent choice. It offers great value for money and longevity.

Manager –

Thank you for your recommendation. We are pleased our precast concrete wall proved to be reliable and cost-effective. For consultation on concrete or additives, please contact us at: +989135508182.

https://lvivforum.Pp.ua/ –

Thanks for one’s marvelous posting! I seriously enjoyed reading

it, you arre a great author. I will remenber to bookmark your bllg and will often come back down the

road. I want to enncourage you to ulttimately continue yopur great work, have a nice morning! https://lvivforum.Pp.ua/

Show reviews in all languages (21)