Recycled Concrete: Recycled concrete is a type of concrete made from recycled materials obtained from the demolition of old concrete structures and other unusable concrete materials. This type of concrete is produced with the aim of reducing the consumption of natural resources, minimizing construction waste, and enhancing environmental sustainability. Recycled concrete can be used as a replacement for traditional concrete in various construction projects.

Difference from Other Types of Concrete: Recycled concrete differs from traditional concrete in that it uses recycled materials instead of fresh raw materials. Due to the use of recycled materials, this type of concrete has unique properties that will be examined in the following sections.

Recycled Concrete Mix Design

The mix design for recycled concrete must include adjustments in the ratio of recycled aggregates to natural aggregates, adjusting the water and cement content, and incorporating additives to enhance performance. Below is an example of a mix design based on previously introduced resources.

General Principles of Recycled Concrete Mix Design

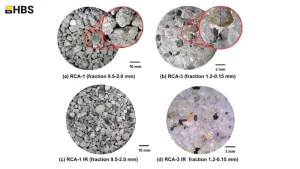

- Recycled Aggregates: Instead of using natural aggregates, a portion of the aggregates is made from recycled concrete materials. Typically, 25% to 50% of natural aggregates can be replaced with recycled aggregates. Attention must be paid to the cleanliness and moisture content of these recycled aggregates.

- Water-Cement Ratio: Due to the higher water absorption capacity of recycled aggregates, the water-cement ratio should be slightly increased or water-reducing additives should be used.

- Cement Content: To compensate for the reduction in strength due to the use of recycled aggregates, it may be necessary to increase the cement content.

- Additives: To improve the durability and strength of recycled concrete, the use of additives such as pozzolanic materials and superplasticizers is recommended.

Suggested Mix Design for Recycled Concrete (with 30% recycled aggregates)

| Material | Quantity (Kg/m³) | Remarks |

|---|---|---|

| Cement | 350 | Portland Cement Type 1 |

| Water | 175 | Water-cement ratio of 0.5 |

| Natural Aggregates (Gravel) | 800 | Natural aggregates of 10-20 mm size |

| Recycled Aggregates (Gravel) | 300 | 30% of the total gravel is recycled |

| Natural Sand | 750 | Sand with a fineness modulus of 2.5 |

| Superplasticizer | 3 | To reduce water content and increase workability |

| Pozzolanic Materials | 50 | Silica fume or fly ash to enhance strength and durability |

- Recycled Aggregates: In this design, 30% of the natural gravel is replaced with recycled gravel. It is essential to check the moisture and cleanliness of recycled aggregates before mixing. Due to the presence of old cementitious materials, these aggregates tend to absorb more water, so water content in the mix should be adjusted accordingly.

- Water-Cement Ratio: To prevent reduced workability and strength, a water-cement ratio of 0.5 is maintained. If recycled aggregates absorb more water, the use of superplasticizers can help reduce the water content while maintaining the desired workability.

- Additives: To enhance the mechanical properties and durability of the concrete, using pozzolanic materials like silica fume and fly ash is recommended. These materials help reduce permeability and increase the strength of the concrete. Additionally, superplasticizers improve the fluidity of the concrete without increasing the water content.

- Compressive Strength: The compressive strength of recycled concrete may be approximately 5% to 15% lower than that of conventional concrete with the same mix design, but by using additives and closely controlling the process, a desirable strength can be achieved.

Advantages of Using Recycled Concrete in Construction

Using recycled concrete in construction offers numerous benefits, both economically, environmentally, and technically. The most significant advantages include:

- Conservation of Natural Resources: By using recycled aggregates, the need to extract natural aggregates is reduced, preserving natural resources.

- Reduction in Waste Generation: The use of demolished concrete as recycled aggregates helps reduce the volume of construction waste and manage it more effectively.

- Lower Transportation and Material Costs: Using local recycled concrete reduces transportation costs and provides cheaper materials.

- Reduced Energy Consumption: Producing recycled concrete requires less energy compared to extracting and processing new aggregates.

- Sustainability and Environment: Using recycled concrete contributes to sustainable construction and helps reduce greenhouse gas emissions.

Reasons to Use Recycled Concrete

- Recycled concrete offers substantial economic and environmental benefits in construction. It reduces overall project costs by using cheaper materials and decreasing the need for new aggregate extraction, making it an ideal choice for budget-conscious or large-scale projects.

- Moreover, the use of recycled concrete significantly reduces the generation of construction waste, contributing to environmental preservation. Since recycled aggregates replace new materials, it minimizes natural resource extraction, helping to conserve the earth’s reserves and reduce environmental degradation.

- Additionally, producing recycled concrete requires less energy than traditional concrete, which helps lower energy consumption in the construction industry and reduces greenhouse gas emissions. With proper management and rigorous testing, recycled concrete can provide reliable performance in various projects, leading to more sustainable and cost-effective structures.

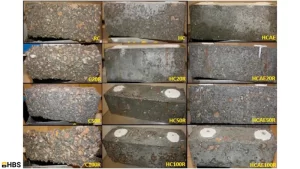

Steps in Recycled Concrete Production

Producing recycled concrete involves the following steps:

- Collecting Demolished Materials: Demolished concrete from construction projects is collected.

- Crushing Concrete: The demolished concrete is crushed at recycling plants into aggregates of varying sizes.

- Removing Impurities: Waste materials like metals, wood, and other debris are separated from the recycled aggregates.

- Producing New Concrete: The recycled aggregates, along with cement, water, and other additives, are mixed to produce new concrete.

- Quality Testing: The produced recycled concrete must undergo quality tests to ensure it meets the necessary standards.

Recycled Concrete vs. Traditional Concrete: Performance and Cost Comparison

Recycled Concrete Performance:

- Recycled concrete generally has lower strength compared to traditional concrete, especially in compressive strength and durability. This reduction is primarily due to the quality of recycled aggregates, which may have micro-cracks or surface defects.

- With proper additives and suitable conditions, recycled concrete can achieve sufficient strength for common construction projects.

Costs:

- The use of recycled concrete is generally cheaper than traditional concrete, as the cost of recycled aggregates is lower and there is no need for new aggregate extraction. Additionally, transportation and disposal costs for construction waste are reduced.

- However, the costs related to processing and separating demolished concrete must also be considered.

Comparison of Compressive Strength: Recycled Concrete vs. Traditional Concrete

Recycled Concrete:

- The compressive strength of recycled concrete is on average 5% to 15% lower than traditional concrete. This strength reduction is due to the micro-cracks and weaknesses present in recycled aggregates.

- Using chemical additives and improving the mix design can bring the compressive strength of recycled concrete to an acceptable level.

Traditional Concrete:

- Traditional concrete uses natural aggregates without structural defects, which generally results in higher compressive strength.

Challenges and Issues with Using Recycled Concrete

Using recycled concrete comes with certain challenges, including:

- Variable Quality of Recycled Aggregates: Recycled aggregates may vary significantly in quality, which can affect the strength and durability of the produced concrete.

- Increased Water Demand: Recycled aggregates tend to absorb more water, leading to a higher water requirement in the concrete mix.

- Need for Advanced Technology: Processing and producing recycled concrete requires advanced equipment to ensure material quality.

- Market Acceptance Issues: Some contractors and clients may be hesitant to use recycled concrete, as it is less well-known than traditional concrete.

Necessary Tests to Ensure Recycled Concrete Quality

To ensure the quality of recycled concrete, the following tests must be performed:

- Compressive Strength Test: This test is performed to assess the compressive strength of recycled concrete.

- Water Absorption Test: Recycled aggregates must be tested for water absorption due to their higher water absorption capacity.

- Elastic Modulus Test: The elastic modulus of recycled concrete is usually lower than traditional concrete, and this property should be tested.

- Durability and Freeze-Thaw Resistance Test: Recycled concrete should be tested for resistance to freeze-thaw cycles.

- Chemical Composition Test: The chemical composition of recycled concrete may affect its performance and durability, and should be tested.

Standards for Producing and Using Recycled Concrete

Various standards exist for the production and use of recycled concrete. Some of the most important standards are:

- ASTM C33: This standard defines the physical and chemical properties of recycled aggregates for use in concrete.

- ASTM C595: This standard pertains to pozzolanic cements and additives for improving the performance of recycled concrete.

- EN 12620: This European standard relates to recycled aggregates and guidelines for their use in concrete.

- National Guidelines: In many countries, national guidelines have been developed for the use of recycled concrete, addressing both technical and environmental characteristics.

Key Applications of Recycled Concrete

- Infrastructure and Road Projects: Recycled concrete can be used in road construction, sidewalks, and road base layers, where high strength is not mandatory.

- Retaining and Protective Walls: Due to its ability to bear compressive loads, recycled concrete can be used for retaining and protective walls.

- Landscaping Projects: In landscaping projects, such as building sidewalks, public spaces, parks, and green areas, recycled concrete is an affordable and environmentally friendly option.

- Non-critical Building Projects: For projects where concrete strength and durability are not critical, such as flooring, recycled concrete is an excellent choice.

- Small to Medium Urban Projects: For smaller projects like parking lots, sidewalks, and minor repairs, recycled concrete can be used at a low cost with acceptable performance.

- Fillers: Recycled concrete can be used as a filler to fill voids and gaps in large infrastructure and underground construction projects.

Considerations for Recycled Concrete

- Sensitive Projects: While recycled concrete has many applications, for sensitive projects and structures that require high strength and long durability, such as tall buildings or bridges, more caution should be exercised when using recycled concrete.

- Necessary Tests: Before using recycled concrete in any project, its quality must be controlled through various tests to ensure that the required strength and durability are met.

Final Thoughts

In conclusion, the use of recycled concrete is a suitable and optimized choice for various projects that prioritize sustainability and cost reduction, especially in projects where environmental and economic factors are considered.