Concrete durability is one of the most crucial factors for the success of construction and civil engineering projects, directly impacting the lifespan and stability of structures. Durable concrete not only requires less maintenance and repair but also provides greater safety for buildings and urban structures. Especially in harsh environmental conditions or industrial settings where concrete is exposed to more destructive factors, the importance of using durable and sustainable concrete increases. This article examines the factors affecting concrete durability, methods to enhance durability, and introduces scientific and innovative techniques to improve the sustainability and service life of concrete.

Factors Affecting Concrete Durability

To increase concrete durability (Improve concrete durability) and improve its quality, identifying and understanding the destructive factors of concrete is highly important. These factors, which can affect the service life of concrete structures, are divided into several main categories:

Physical Factors Affecting Concrete Durability

- Freeze-Thaw Cycles: Alternating temperature changes cause cracking and gradual deterioration of concrete, reducing its durability.

- Severe Temperature Variations: Concrete exposed to extreme temperature changes experiences internal stresses and may develop cracking.

- Concrete Abrasion and Erosion: Factors such as water flow or traffic loads can cause surface abrasion, reducing concrete durability and strength.

Chemical Degradation Factors of Concrete

- Chloride Attack: Chloride penetration into concrete, especially in coastal areas or regions where salt is used for de-icing, can lead to concrete structure degradation and rebar corrosion.

- Sulfate Attack: Sulfates present in soil or water can react with materials in concrete, causing structural damage.

- Alkali-Silica Reaction (ASR): This reaction occurs between the alkalis in cement and the active silica in aggregates, leading to internal cracking and concrete deterioration.

Mechanical Factors

- Heavy Loads and Continuous Stresses: Concrete subjected to continuous loads may lose its strength and durability over time.

-

Type of Factors Name of Factors Description Physical Freeze-Thaw Cycles – Causes cracking and reduces durability

– Leads to gradual surface deterioration of concreteSevere Temperature Variations – Causes internal stresses

– Potential for cracking in concreteAbrasion and Erosion – Reduces surface durability of concrete

– Effects of traffic and water flow on concrete surfaceChemical Chloride Attack – Penetrates deep into concrete and causes rebar corrosion

– Typically occurs in coastal areas and locations where salt is used for de-icingSulfate Attack – Reacts with materials within concrete, causing its deterioration

– Typically occurs in areas with high sulfate-containing soil or waterAlkali-Silica Reaction (ASR) – Reaction between cement alkalis and aggregate silica

– Causes internal cracking and concrete deteriorationMechanical Heavy Loads and Continuous Stresses – Reduces concrete durability and strength over time

– Causes cracking and decreases structural integrity

Solutions to Improve Concrete Durability and Sustainability

Using Admixtures to Enhance Concrete Durability

Admixtures play a significant role in improving concrete properties and increasing its durability. Some of these materials include:

- Plasticizers and Superplasticizers: By reducing the water-to-cement ratio and increasing concrete density, concrete durability is enhanced.

- Air-Entraining Admixtures: Controlled air entrainment creates fine air bubbles in concrete, preventing damage from freeze-thaw cycles.

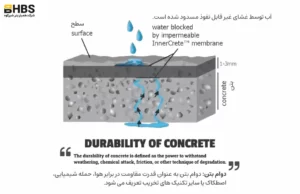

- Water-Repellent Admixtures: Using water-repellent admixtures reduces concrete permeability and prevents the ingress of harmful agents into the concrete.

Self-Healing Concrete: A Modern Approach to Enhancing Concrete Durability

One of the modern approaches to increasing concrete durability is the use of self-healing concretes. These concretes contain materials that react with cracks and automatically repair them. Common methods include the use of active bacteria, silica microcapsules, and self-healing admixtures.

Modifying the Concrete Mix to Enhance Durability

Improving the concrete mix plays a crucial role in increasing its durability and lifespan. Replacing a portion of cement with supplementary cementitious materials (SCMs) such as pozzolans, fly ash, and slag can make concrete more resistant to chemical attacks and environmental factors. These materials typically increase the density and compactness of concrete, protecting it against destructive conditions.

Using Fibers in Concrete to Enhance Durability and Sustainability

Adding fibers to the concrete mix increases tensile strength and reduces cracking in concrete. Both synthetic and metallic fibers can help mitigate cracking issues and enhance concrete durability, especially in structures subjected to high pressures and stresses.

Implementation Techniques to Enhance Concrete Durability and Quality Control

Proper Curing of Concrete

Proper and timely curing is of great importance for concrete durability. Adequate curing can prevent early cracking and surface weakness, thereby increasing its lifespan and durability. Using coverings or moisture-curing methods are effective techniques for this purpose.

Quality Control of Concrete at the Construction Site

Quality control of concrete during and after placement is crucial. Conducting various tests, such as slump tests, compressive strength tests, and non-destructive tests, ensures the quality and durability of concrete. Having a precise quality control program can prevent issues in concrete and contribute to structural durability.

Preventing Segregation and Internal Voids in Concrete

Proper concrete placement and the use of appropriate vibration methods can prevent the formation of voids and segregation. These voids can cause serious damage to concrete over time by allowing the ingress of water and salts.

Frequently Asked Questions on Concrete Durability and Improvement Solutions

1. What does concrete durability mean?

Concrete durability refers to its ability to withstand various environmental conditions and destructive factors without losing its essential and structural properties. Highly durable concrete has a longer lifespan and requires less maintenance and repair.

2. Why is increasing concrete durability important?

Concrete durability is economically and safety-wise very important. Durable concrete structures have lower maintenance and repair costs and are more resistant to harsh environmental conditions and destructive factors. This is especially significant in large-scale civil and construction projects.

3. What factors can reduce concrete durability?

Various factors such as freeze-thaw cycles, chemical attacks (like chloride and sulfate attacks), severe temperature variations, and mechanical factors like high pressures can reduce concrete durability. These factors cause cracking and surface deterioration of concrete.

4. How can concrete durability be increased?

Increasing concrete durability requires a combination of using high-quality materials, specific admixtures, and appropriate implementation techniques. For example, using admixtures like plasticizers and superplasticizers, self-healing concretes, and fiber-reinforced concrete can all improve concrete durability.

5. What is self-healing concrete and how does it work?

Self-healing concrete is a type of concrete that can automatically repair its own cracks. It contains materials such as silica microcapsules or active bacteria that react to environmental conditions when cracking occurs, filling the gaps and preventing the ingress of harmful agents.

6. How can chloride and sulfate attacks on concrete be prevented?

To prevent these chemical attacks, it is recommended to use water-repellent admixtures and modify the concrete mix. Additionally, proper coating and the use of low-permeability concretes can prevent chloride and sulfate penetration into the concrete.

7. Why is curing important for concrete durability?

Curing is a process that ensures concrete has the appropriate moisture and temperature for sufficient time to achieve the necessary strength and durability. Proper curing prevents early cracking and surface weakness, contributing to long-term durability and strength.

8. How does quality control at the construction site improve concrete durability?

Quality control at the construction site, through tests like slump and compressive strength tests, ensures that the concrete is made and placed with the desired properties. This prevents issues like segregation, internal voids, and cracking, all of which can harm concrete durability.

9. Do fiber-reinforced concretes really help in durability?

Yes, fiber-reinforced concretes can increase the tensile strength of concrete and prevent cracking and spalling. Both synthetic and metallic fibers contribute to concrete durability, especially in structures subjected to high stresses and pressures.

10. How can low-permeability concretes be made for wet or coastal areas?

To make low-permeability concretes, water-repellent admixtures, plasticizers, and special cements can be used. These materials increase concrete density and reduce its permeability, preventing water and chlorides from penetrating the concrete.

11. Do supplementary cementitious materials in the concrete mix help in durability?

Yes, supplementary cementitious materials (SCMs) like fly ash, pozzolans, and slag can enhance concrete durability. These materials increase concrete density and compactness, making it more resistant to chemical attacks and environmental factors.

12. When is it best to use self-healing concrete?

Self-healing concrete is typically used in projects where access for repairs is difficult or in areas with harsh environmental conditions. This type of concrete automatically repairs small cracks, preventing the ingress of harmful agents.

13. How can the costs of increasing concrete durability be reduced?

By using appropriate admixtures, performing proper curing, and selecting suitable concrete mix designs, the costs of increasing concrete durability can be reduced. Additionally, precise planning and quality control at the construction site help lower costs and extend the service life of structures.

What is the Best Method to Increase Concrete Durability?

The best method to increase concrete durability is a combination of suitable admixtures, proper curing practices, and precise quality control during implementation. Specifically:

Using High-Quality Admixtures such as Superplasticizers and Air-Entraining Admixtures that increase concrete density and improve its resistance to environmental conditions.

Proper and Timely Curing that provides adequate moisture and temperature for the concrete, preventing early cracking and maximizing concrete strength.

Quality Control and Monitoring of the Construction and Concrete Placement Process including tests like Compressive Strength and Slump Tests that prevent issues like segregation and internal cracking.

This combination of methods not only enhances concrete durability but is also economically efficient and safe, making it recommended for high-standard civil and construction projects.