Fire-Resistant Concrete is an advanced building material known for its high resistance to extreme temperatures and fire, making it an essential element in protecting structures under harsh conditions. Due to its unique thermal properties, this type of concrete plays a key role in various industries, particularly in construction and thermal industries. This article will explore the production process, mix design, applications, benefits, and the future of fire-resistant concrete.

Production of Fire-Resistant Concrete

Fire-Resistant Concrete is specifically designed and produced to maintain its physical and mechanical properties at high temperatures, typically above 500°C. The production of fire-resistant concrete requires the use of special raw materials and precise processes.

Raw Materials for Fire-Resistant Concrete

- Fire-resistant aggregates: These aggregates are typically composed of minerals such as bauxite, alumina, and fireclay aggregates, all known for their high-temperature resistance.

- Refractory cement: Refractory cements like calcium aluminate cement are used due to their high heat tolerance and durability in extreme conditions.

- Refractory additives: Special additives such as refractory fibers and heat-resistant compounds are incorporated into the concrete mix to enhance its resistance to fire and high temperatures.

Production Process

The production process for fire-resistant concrete starts with mixing, where all raw materials are uniformly combined. The mixture is then poured into special molds and compacted through vibration or pressing to eliminate air voids and achieve proper density. Afterward, the concrete undergoes curing to reach its final strength, which may involve natural drying or even kiln curing.

Once cured, fire-resistant concrete is subjected to various tests to ensure its quality and thermal resistance. This combination of materials and production processes makes it an ideal choice for industries such as industrial furnaces, power plants, tunnels, and refineries, where high thermal performance is essential.

Fire-Resistant Concrete Mix Design

Fire-resistant concrete is a specialized building material designed to withstand high temperatures and prevent structural failure during fires. The primary components of this concrete include refractory cement, heat-resistant aggregates, and special additives, which ensure that the concrete remains stable at extreme temperatures (up to 1000°C).

Raw Materials and Mix Design

- Refractory aggregates: Choosing the right aggregates is crucial. Carbonate aggregates, such as dolomite and limestone, are effective as they form an insulating CO₂ layer at high temperatures, absorbing heat without increasing the overall temperature.

- Refractory cement: Using refractory cements like calcium aluminate cement is essential for achieving high heat resistance. These cements remain chemically stable at high temperatures, contributing to the structural integrity of the concrete.

- Additives: Additives such as metal fibers or heat-resistant polymers are added to prevent cracking and increase the tensile strength of the concrete at high temperatures. Mineral additives like silica fume and metakaolin also help improve compressive strength, particularly at temperatures between 200°C and 400°C.

Fire-Resistant Concrete Mix Design Table (per 1 cubic meter of concrete)

| Raw Materials | Quantity (kg) |

|---|---|

| Refractory Cement (Calcium Aluminate) | 400 |

| Refractory Aggregates (Dolomite or Limestone) | 1000 |

| Water | 180 |

| Metal Fibers | 10 |

| Silica Fume | 40 |

| Metakaolin | 30 |

Applications of Fire-Resistant Concrete

Fire-Resistant Concrete is a highly specialized construction material that is widely used in industries exposed to high temperatures and fire hazards. Its unique composition allows it to withstand extreme heat and maintain the structural integrity of buildings. Below are some of the key applications of fire-resistant concrete:

- Industrial furnaces: Fire-resistant concrete is extensively used in metal furnaces and metallurgical industries. These concretes are applied as linings for furnaces to ensure they can withstand temperatures above 1000°C, preventing structural damage.

- Power plants: In nuclear and fossil fuel power plants, fire-resistant concrete is used to protect structures and equipment. It not only resists heat but also withstands chemical exposure and mechanical impact, prolonging the life of critical infrastructure.

- Tunnel linings: This concrete is used in tunnels to provide protection against fire and intense heat in emergency situations. It ensures that the tunnel structure remains intact for a certain period, preventing collapse.

- Refineries and petrochemical plants: Fire-resistant concrete is vital for safeguarding equipment and structures in these industries from high temperatures and sudden fires. Its resistance to both heat and corrosion makes it indispensable in this field.

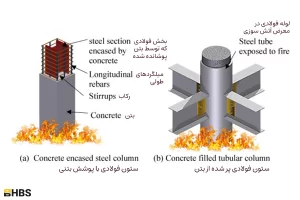

- High-rise buildings: In skyscrapers, fire-resistant concrete is used as a protective layer for steel beams and columns, ensuring that the structure remains intact during a fire, allowing enough time for evacuation.

Benefits of Fire-Resistant Concrete

Fire-resistant concrete offers numerous advantages over conventional concrete, including:

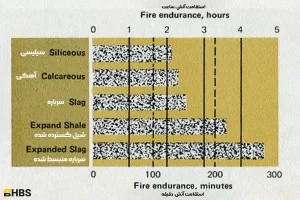

- High thermal resistance: This concrete can endure extremely high temperatures and protect structures during fire emergencies.

- Physical stability: Unlike traditional concrete, which may crack or deteriorate under extreme heat, fire-resistant concrete maintains its structural integrity.

- Long lifespan: The use of heat-resistant materials and additives increases the longevity of structures built with fire-resistant concrete.

- Wide applications: Fire-resistant concrete is used in various industries, including construction, petrochemical, thermal, and energy sectors.

The Future of Fire-Resistant Concrete

With advancements in technology and the growing need for building materials with greater fire and heat resistance, fire-resistant concrete is expected to undergo significant developments in the future. Some key trends include:

- Increased use of nanomaterials: Nanotechnology and nanoparticles will enhance the thermal and mechanical properties of fire-resistant concrete.

- Reduced weight with higher strength: The use of lightweight aggregates and advanced additives will lead to the production of fire-resistant concrete with reduced weight and increased strength.

- Improved environmental sustainability: New research focuses on incorporating recycled and renewable materials into the production of fire-resistant concrete to reduce its environmental impact.

Conclusion

Fire-resistant concrete is an advanced and resilient building material that plays a crucial role in protecting structures from heat and fire. Its unique mix design and durable raw materials make it highly effective in high-temperature environments. Furthermore, its wide applications across various industries, from tunnels and power plants to industrial furnaces, highlight its importance in the future of construction. With its remarkable advantages, fire-resistant concrete has secured a prominent position among building materials, and with ongoing technological advancements, the expectations for its performance will only continue to rise.