Imagine a material that can resist water penetration and ensure the longevity and strength of structures even in the harshest environmental conditions. Whether you are an experienced engineer, a civil engineering student, or someone interested in the construction industry, understanding waterproof concrete is essential. In this article, we delve into the details of waterproof concrete, from its production methods to real-world applications, and how it has set new standards in the construction industry.

What is Waterproof Concrete?

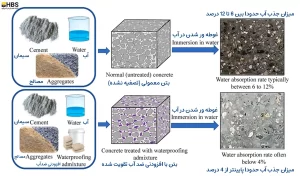

Waterproof concrete is essentially a special mix that is highly resistant to water penetration. Unlike conventional concrete, which is porous and may allow water to seep through, waterproof concrete is formulated to create a waterproof barrier. This makes it ideal for structures exposed to water or high moisture levels, such as basements, tunnels, swimming pools, and water treatment plants.

Waterproof Concrete Mix Design

Creating waterproof concrete starts with the right mix. The success of waterproof concrete depends on its composition:

- Cement: High-quality cement is essential. Portland cement is a common choice, known for its strength and durability.

- Water: The water-to-cement ratio must be carefully controlled. Excess water can increase porosity and reduce the waterproofing ability of the concrete.

- Aggregates: Properly graded fine and coarse aggregates create a dense concrete mix. Using clean, non-porous aggregates helps reduce water absorption.

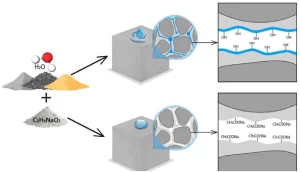

- Additives: These are key factors. Additives such as water reducers, superplasticizers, and hydrophobic agents significantly improve the waterproofing properties of the concrete.

- Supplementary Cementitious Materials (SCMs): Materials like fly ash, silica fume, and slag can help improve the density and durability of the concrete.

A precise mix design is essential to ensure the concrete achieves the desired strength and waterproofing characteristics. This requires careful consideration of materials and their proportions, often guided by industry standards and the specific needs of the project.

Waterproof Concrete Production Method

Producing waterproof concrete requires great precision. Here’s how it’s done:

- Weighing and Measuring: Materials are measured and mixed according to the specific mix design. This process must be carefully controlled to ensure uniformity.

- Mixing: The mixing process must be thorough to ensure all components are evenly distributed. High-efficiency mixers are often used to achieve a homogeneous blend.

- Pouring and Compaction: After mixing, the concrete must be poured quickly to prevent segregation and properly adhere to the desired surface. Compaction, usually done with vibrators, removes air bubbles and enhances the density and waterproofing characteristics of the concrete.

- Curing: Proper curing is crucial. This process allows the concrete to reach its full strength and waterproofing properties. It involves maintaining the appropriate moisture level and temperature for a specified period, typically between 7 and 28 days.

- Quality Control: Throughout the production process, quality control measures are implemented to check the uniformity, strength, and waterproofing performance of the concrete. This may include tests like slump tests, compressive strength tests, and permeability tests.

Maintenance of Waterproof Concrete

Waterproof concrete, like all construction materials, requires maintenance to preserve its performance over time. Proper maintenance not only extends the life of the structure but also ensures that its waterproofing properties are retained.

- Regular Inspections: Periodic inspections can help identify potential issues such as cracks or surface wear that may affect the waterproofing properties.

- Sealing Cracks: If cracks occur, they should be quickly sealed using appropriate sealants or repair mortars to prevent water infiltration.

- Surface Treatments: Applying surface treatments like waterproof coatings can provide an additional protective layer against water penetration.

- Cleaning: Keeping the concrete surface clean, especially in areas exposed to contamination and dirt, can help maintain its waterproofing properties.

- Joint Maintenance: In structures where waterproof concrete is used alongside joints, it is important to ensure that the joints remain sealed and intact.

Applications of Waterproof Concrete

Waterproof concrete has wide-ranging applications in environments exposed to water. Some of the most common applications include:

- Basements and Underground Structures: Waterproof concrete is ideal for basements, tunnels, and other underground structures where the risk of water infiltration is high.

- Water Treatment Plants: These facilities require concrete that can resist water and chemicals without degrading.

- Swimming Pools: The impermeability of waterproof concrete makes it an excellent choice for swimming pools, ensuring the structure remains watertight over time.

- Bridges and Marine Structures: Infrastructure like bridges, dams, and marine structures that are frequently exposed to water require waterproof concrete to prevent water-related damage.

- Tanks and Retaining Walls: These structures must withstand water pressure, and waterproof concrete provides the necessary strength and durability.

A new approach in the concrete industry! Don’t miss: Ultra-High Performance Concrete (UHPC) | Innovation in Building Materials

Waterproof Concrete Standards

Ensuring Quality and Compliance To ensure the performance of waterproof concrete, several standards and guidelines have been established. These standards govern the production, testing, and application of waterproof concrete, ensuring that it meets the required quality and durability.

- ACI 212.3R-16: This standard provides guidelines for the use of chemical admixtures in concrete, including waterproofing admixtures.

- BS 8102:2009: The British Standard for the protection of below-ground structures against water from the ground.

- EN 206: The European Standard for concrete, covering specifications, performance, production, and conformity.

- ASTM C494/C494M: This standard includes chemical admixtures for concrete, including waterproofing agents.

These standards ensure that waterproof concrete is properly produced and used, guaranteeing its performance in real-world applications.

Benefits of Waterproof Concrete

Waterproof concrete offers several benefits, making it an increasingly popular choice in the construction industry:

- Durability: Waterproof concrete is highly resistant to water penetration, which enhances the durability of structures,Here is the continuation of the English translation of the provided code:

“`html

especially in harsh environments. - Cost-Effectiveness: By reducing the need for additional waterproofing treatments, waterproof concrete can be a cost-effective solution in the long run.

- Environmental Resistance: Waterproof concrete is not only resistant to water but also to other environmental factors such as chemicals and freeze-thaw cycles.

- Low Maintenance: Structures built with waterproof concrete require less maintenance over time, helping to reduce lifecycle costs.

- Versatility: Waterproof concrete can be used in a wide range of applications, from residential basements to large-scale infrastructure projects.

- Sustainability: By extending the lifespan of structures and reducing the need for repairs, waterproof concrete contributes to more sustainable construction practices.

Real-World Waterproof Concrete Projects

Waterproof Concrete in Action To truly understand the impact of waterproof concrete, let’s look at some real-world projects where this material has made a significant difference:

| Project | Location | Brief Description |

|---|---|---|

| Channel Tunnel | UK/France | This tunnel, one of the greatest engineering achievements of the 20th century, was constructed with a waterproof concrete lining that prevents water infiltration from the seabed, ensuring the tunnel’s safety and longevity. |

| Marina Bay Sands | Singapore | This iconic structure features an extensive underground complex built with waterproof concrete. Due to its proximity to water and the need for durable foundations, the use of waterproof concrete was essential. |

| Three Gorges Dam | China | As the world’s largest hydroelectric project, the Three Gorges Dam was constructed using extensive amounts of waterproof concrete to prevent water penetration and ensure the integrity of the dam. |

Key Considerations for Waterproof Concrete

- The Role of Additives in Enhancing Waterproof Concrete: Additives are the secret to the success of waterproof concrete. Learn how these additives work to improve the properties of concrete, making it more resistant to water and environmental factors.

- Challenges of Implementing Waterproof Concrete: While waterproof concrete offers many benefits, it also comes with challenges. Discover common issues encountered during the implementation process and ways to overcome them.

- Comparing Waterproof Concrete to Conventional Concrete: How does waterproof concrete perform compared to conventional concrete? This section examines the performance, cost, and application differences between the two types of concrete.

- Innovations in Waterproof Concrete: What’s Next? The construction world is constantly evolving. Learn about the latest innovations in waterproof concrete, including self-healing materials and smart concrete technologies.

Conclusion

Waterproof concrete is revolutionizing the construction industry, providing a durable, cost-effective, and sustainable solution for structures exposed to water. From precise mixing and production methods to its diverse applications in real-world projects, waterproof concrete is setting new standards in construction. Whether you are an engineer, a civil engineering student, or a construction industry professional, understanding and using waterproof concrete can give you a competitive edge in your projects.

As the demand for resilient and long-lasting structures grows, waterproof concrete is not just an option; it is the future of construction. So, harness the potential of this innovative material and be part of the revolution shaping the skyscrapers of tomorrow.